Sheet metal

Involved in HVAC Industry for over forty years and are manufacturing quality products which includes import substition products as well as representing Prestigious Companies in GCC.

BMS

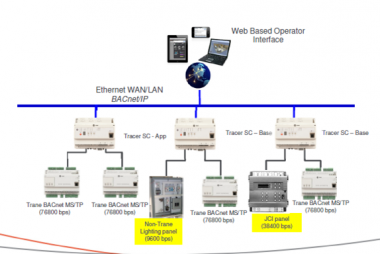

A Building Management System is a computer based control system that controls and monitors the building’s mechanical and electrical equipment e.g. Ventilation, Lighting, Power System, Fire System, Security System, etc..